Carpenters and specialists in wood construction benefit from reliable anchors that are easy to install when fastening wooden components to concrete. The UltraCut FBS II concrete screws from fischer meet particularly high requirements, as their variants and accessories cover multiple applications in roof and wood construction. A European Technical Assessment (ETA) provides additional safety.

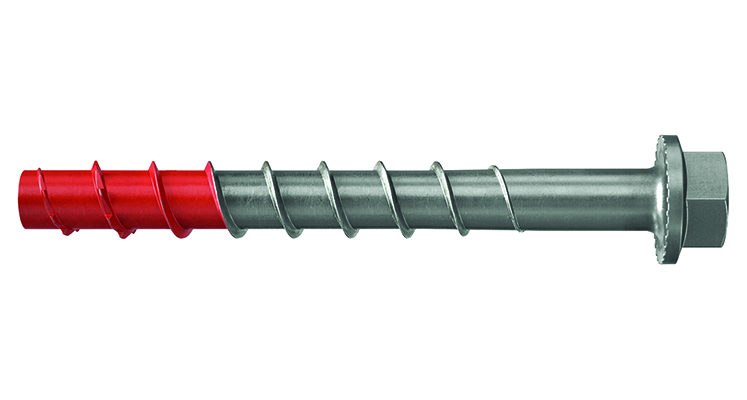

Beam anchors, timber facades and other timber structures - thick structures often need to be anchored to concrete in roof and timber construction. Fischer offers 29 versions of the Ultracut FBS II in galvanized carbon steel and stainless steel with long usable lengths and European Technical Assessments (ETA) for these applications. Depending on the variant, screw lengths for wood structures reach up to 190 mm for 8 mm diameter, up to 280 mm for 10 mm diameter, up to 210 mm for 12 mm diameter and up to 240 mm for 14 mm diameter. This offers the advantage of maximum flexibility and a versatile application range.

Smart solution

Timber construction specialists and carpenters can adjust beams and purlins even more easily with the new FSW adjusting ring combined with the Ultracut FBS II hexagon head US 10 mm diameter (galvanized) - a smart solution for evenly aligning rafters with spirit levels on what are often uneven surfaces during the erection of rafters and prefabricated houses. The adjusting ring FSW can be attached to concrete in no time along with the galvanized Ultracut FBS II 10 US. Then a second FSW with a downward facing notch is placed over the head of the FBS II and attached to the wood beam with at least two Power-Fast FPF-PT 5.0×40 ZPF screws for accurate adjustment. This is done by accurately aligning the wood beam with an impact wrench, such as fischer's FSS 18V 400BL with torque control, by loosening the FBS slightly and then aligning it with mortar. The upper FSW can be disassembled as needed.

Support beams

Wood components can be safely and easily attached to concrete with fischer's ULTRACUT FBS II concrete screw - whether installing support beams, frame elements or roof rafters. Timber frame structures can also be securely anchored with the screw. The fastening solution also makes it easy to create commonly used connections and beam anchors in wood structures. The concrete screw is simply inserted into the drill hole using the piercing method of installation, and that is all. Further cleaning of the drill hole is not necessary when drilling vertically into floors and ceilings or using hollow drills with vacuum functions. Up to three different approved screw depths can be used to match the existing load for each FBS II variant. The range of fischer concrete screws covers every thickness of wood components.

Tensile load

The patented thread geometry and large core diameter of the concrete screw support high shear and tensile loads in concrete, enabling many applications with fewer fasteners. The flanks of the FBS II cut deeply into the concrete during insertion. This optimum fit ensures reliable force transmission, anchors free from expansion pressure and

low edge and axial distances for easy and safe installation. The FBS II can be unscrewed, aligned and realigned up to two times without being damaged in accordance with regulations. Ribs under the head prevent unintentional loosening of the concrete screw.

Further advantages are that the FBS II can be reused under certain circumstances, for example to temporarily anchor sloping formwork supports in fresh concrete that has not yet fully cured, as well as fresh concrete with a strength as low as 10 N/mm². The measuring shaft should be used to test the wear of the thread and ensure that it is still working adequately. Its ETA for applications in concrete covers fire resistance class R 120 and, in most cases, seismic applications in performance categories C1 and C2.