How do we reduce our CO2 emissions and become less dependent on fossil resources? With that question, Bruynzeel Kitchens started its search for a sustainable kitchen about four years ago.

"Circo was created after years of searching and research. For the raw materials and materials, we sought cooperation with various suppliers. We combined various biobased products into a sustainable, organic sheet material suitable for kitchens for project use. And that is exactly what makes Circo so special: it is the first bio-based kitchen suitable for mass production in our own factory," says Bruynzeel Kitchens.

Tied by sunflower seeds

Circo has an MDF core made from 100% reclaimed wood. This means that no trees are cut down for it, but residual wood such as branches and logs are used. The wood fibers are bonded with a plant-based binder. This is made from residual streams of sunflower seeds and rapeseed from the agricultural and food industries. The result is a biodegradable MDF that emits 33% less CO2 during production.

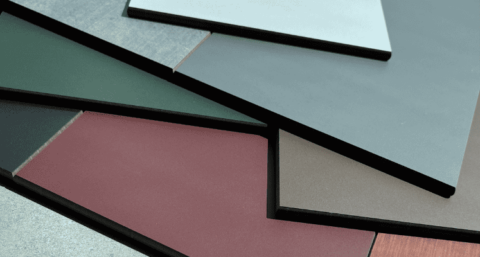

Biobased HPL

Circo has a biobased HPL top layer made from kraft paper derived from coniferous trees and a resin based on sugarcane residues. Completely renewable and CO2-neutral production. And because it contains no fossil raw materials, Circo is free of formaldehyde and phenols. So a better, healthier living environment.

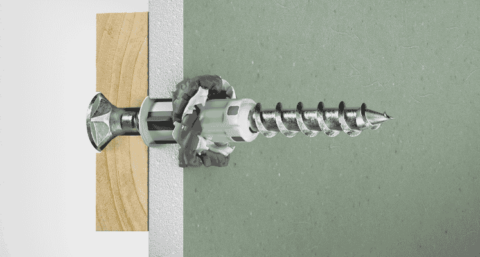

Edging from residues

The edgebanding has also been considered. It consists of 50% recycled, post-industrial raw materials, which substantially reduces CO2 emissions.

Visit Bruynzeel Kitchens during BouwBeurs 2025 and learn about Circo, handles made from ocean plastic and countertops made from PET bottles.

You will find them in hall 7, at booth A008